Ensuring Safety and Quality: A Deep Dive into Toy Industry Inspection Practices

When it comes to the toy industry, safety and quality are paramount. Parents and caregivers trust that the toys they purchase for their children adhere to the highest standards. This is where toy industry inspection practices come into play, ensuring that every toy on the shelf is not only fun but also safe and durable. In this post, we’ll explore the rigorous inspection practices that are the backbone of the toy industry’s commitment to safety.

Understanding Toy Safety Standards

Before delving into inspection practices, it’s important to understand the safety standards that govern the toy industry. Organizations such as the Consumer Product Safety Commission (CPSC) in the United States and the European Union’s Toy Safety Directive set forth comprehensive guidelines that all toys must meet. These standards cover everything from the materials used to the design and construction of the toys.

The Role of Third-Party Testing

One of the key components of toy industry inspection practices is third-party testing. Independent laboratories conduct a series of tests on toys to ensure they meet the required safety standards. These tests can include checking for choking hazards, verifying the absence of harmful chemicals, and assessing the toy’s structural integrity.

Factory Inspections and Quality Control

Manufacturers also play a crucial role in maintaining high safety standards through regular factory inspections and quality control procedures. These inspections often involve checking the production line for any deviations from the design specifications and testing random samples from each batch of toys.

For more insights into the importance of quality control in manufacturing, check out our Blog.

Continuous Improvement and Compliance

Toy industry inspection practices don’t stop at the factory door. Continuous improvement programs and compliance monitoring ensure that manufacturers keep up with evolving safety standards and regulations. This proactive approach helps to prevent safety issues before they reach consumers.

If you have any questions or need further information, please feel free to Contact Us.

Ensuring the safety and quality of toys is a complex process that requires diligence and a commitment to excellence. From adhering to strict safety standards to conducting thorough inspections and tests, the toy industry works tirelessly to provide safe and enjoyable products for children around the world.

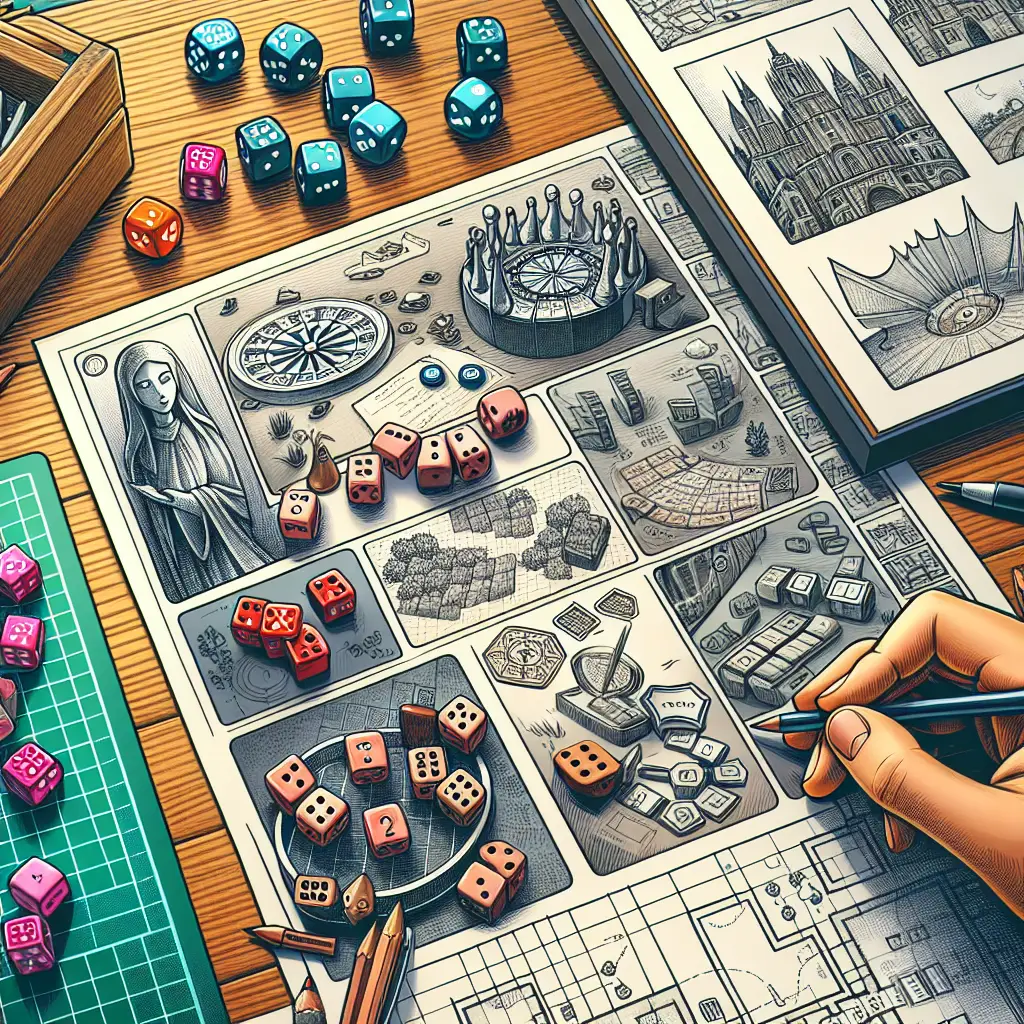

At the end of the day, the goal is to create toys that inspire imagination and bring joy to children’s lives without compromising on safety. For those interested in the production of board games, you can read more about our services at www.weareags.com.